|

||||||||||||||||||||||||||||

| ISO 9001 : 2008 CERTIFICATE | ||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

| Click for enlarge | ||||||||||||||||||||||||||||

|

GATE VALVES

Salient Feature

Salient Feature

- Meets design requirement of ASME B 16.34 / API 600 / API603 /API 6D and testing requirement API 598 / BS 6755 / API6FA / ISO 5208

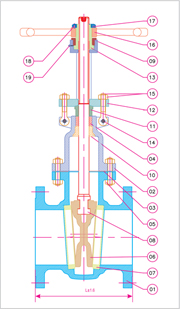

- Outside Screw and Yoke Construction Valves provided with back seating arrangement Solid, flexible, split wedge and parallel slide are available Renewable, seal welded seat ring or integral seat ( Cast SS. only ) available.

- Specially designed die formed graphite packing, controlled clearance between stem, gland and bonnet bushing for guaranteed low emissions meet 100 PPM maximum fugitive emission levels.

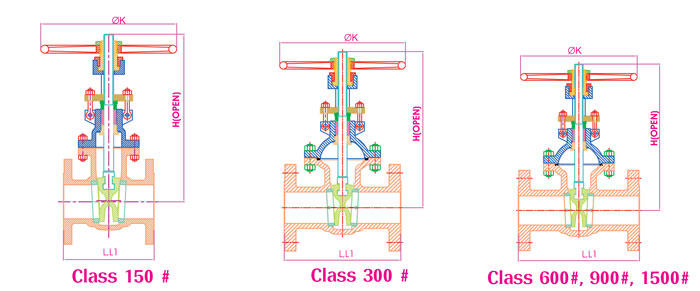

- Anti - friction ball thrust bearing in yoke sleeve for higher size and classes Grub Screw : Secures yoke nut in the bonnet Gress Nipple : Supplies lubricant to the mating parts Flanged End or butt welding end Flanged end dimensions conform to ANSI / ASME B 16.5 / API 605 / DIN / BS 3293 Butt welding end dimensions conform to ANSI / ASME B 16.25 Face to Face and End Dimensions conform to ASME / ANSI B 16.10 / DIN / BS 2080 Bi - directional shut-off.

- Extended bonnet provided for low temperature and cryogenic services (cold box and non cold box applications) to conform to requirement of BS-6364

- Deep stuffing box - with lantern ring

- Self - aligning two piece gland

- Gear Box / Chain Wheel design available

- Electric or pneumatic actuator design available

- Ring joint facings available in higher classes

- Locking arrangement optional

- By-Pass, Drain Plug design available

- Stellited seating hard facing are provided on request

- Alloy-20, Monel, Hstelloy B & C, CF3 & CF3M Materials on request